Sintered stone is a man-made product formed by high speed compression of natural raw materials, including quartz, feldspar and clay, and then is baked at high temperatures (up to 1200°C). This manmade sintering process replicates the way stone is formed in nature over thousands of years, in a matter of hours.93% of the raw materials used in production are made from crushed stone. The result is a slab that possesses the visual richness of quarried stone, but with the design freedom and technical performance of an engineered product.

Unlike other natural stone options, sintered surfaces are resistant to thermal shock (hot pans), to stains from oil and will not fade with UV exposure. These features also make it an ideal choice for the modern approach to indoor/outdoor continuity in renovations. Standard slab sizes reach up to 3200mm in length, allowing for continuous surfaces great for islands, shower walls and floors with no risk of joints or the need for compromise in structural or aesthetic performance when highly reduced thicknesses are used, as thin as 6mm.

5 Advantages of Sintered Stone in Modern Renovations

Unmatched Durability for High-Traffic Areas

Sintered stone comes out as the perfect surfacing option as it offers unmatched strength and resilience making it durable. Created by intense heat and pressure above 1,200°C, this manmade product has a density of 5-6 g/m³ (according to the industry standard 2023); 15-20% harder than granite. It’s virtually indestructible mineral formation breaks free from the mold of boring design with its eye-catching crisp white color and enviable durability and performance; resistant to chipping, cracking and scratching, even in commercial installations and high-traffic areas in the home. The non-porous surface also resists micro-fissures which cause dirt to accumulate.

Stain & Heat Resistance in Kitchen Environments

In the kitchen zones, the sintered stone protects against the harsh and damaging environs that many kitchens face. Its surface absorbs none of it, so that spilled wine, oils, and tomato sauces can simply be wiped away. Thermal testing shows customers have: no blistering at 250°F; no cracking at 350°F; no discoloration at 350°F; no dripping at 500°F, and no cracking at -15°F but please don't try this at home! So it is used as the testing measures with acidic ants like vinegar and lemon juice cook with your first heavy meal preparation too.

Lightweight Nature for Flexible Installations

At just 7-8 kg/m² thickness (compared to marble's 12-15 kg/m²), sintered stone simplifies structural considerations in renovations. The reduced mass enables creative applications otherwise impossible with natural stone, including:

- Vertical feature walls without reinforced framing

- Floating shelves in small condos

- Retrofit projects where structural loading capacity is limited

- Ceiling claddings in boutique spaces

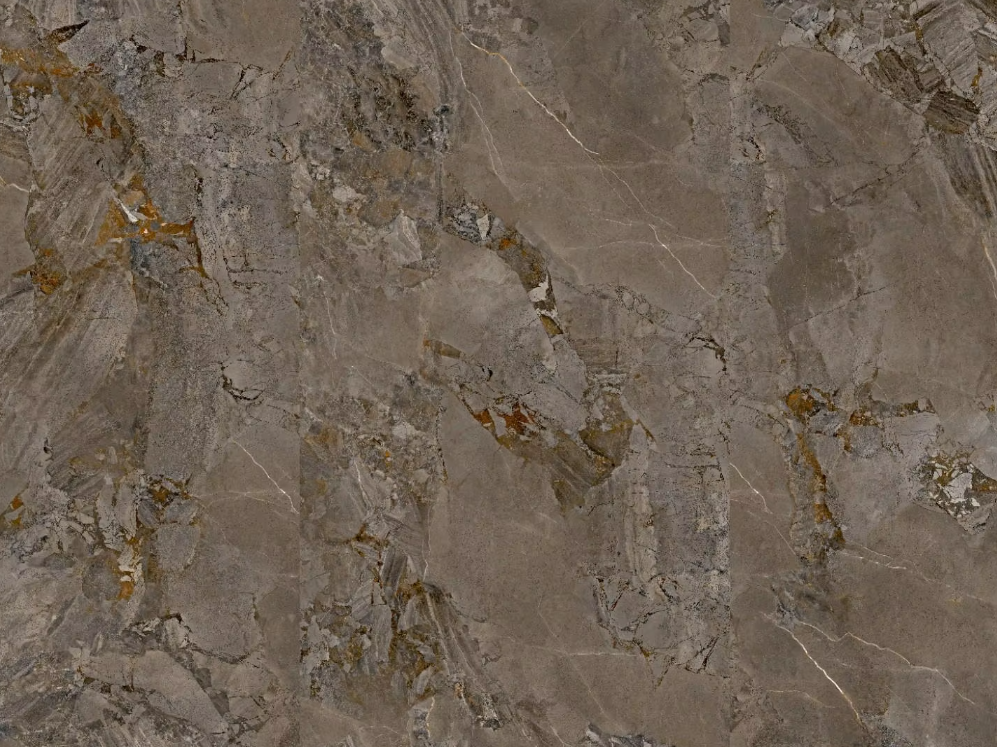

Aesthetic Versatility Across Design Styles

Design flexibility distinguishes sintered stone as an adaptable medium for contemporary visions. Its advanced manufacturing replicates natural stones with photographic precision across 180+ documented patterns (Global Finishes Report 2023). The technology enables customization of:

- Veining replication through full-slab printing

- Gloss levels from rustic matte to mirror polish

- Thickness options (3-20mm) for furniture applications

- Color matching between slabs for integrated spaces

Sintered Stone Kitchen Transformations

Countertops That Redefine Culinary Spaces

Sintered stone countertops are turning food-prep areas into chef’s work stations. Scratch resistant, up to 42% stronger than granite (Bending) means that this durable surface can certainly take the heat.HOW STRONG IS QUARTZCOUNTERTOP? Stronger than granite (how can that be?) these surfaces are made to stand up to the demands of knife work and hot pots NO SEALANT IS REQUIRED. The non-porous design eliminates bacterial breeding ground – a must-have in areas dealing with raw food. Contemporary installations include waterfall-edge countertops that flow into honed flooring, where only uninterrupted surfaces exist for easy maintenance.

Seamless Backsplashes with Full-Slab Solutions

Full-slab sintered stone backsplashes solve traditional grout line issues in kitchen areas vulnerable to grease splatters. Full-sized one-piece materials that go to the hood cut maintenance time by 68% compared to the multiple grout lines found in tiled walls and grouted panels (2024 Kitchen Material Trends Report). This approach also allows for the daring choice of metallic veining, or bookmatched patterns to continue across cooking surfaces. Newer innovations are heat-resistant slabs that feature charging stations for a kitchen’s worth of tech.

Integrated Dining Surfaces & Islands

Sintered stone's structural stability is now being used by designers to blur cooking and dining areas. Islands, with cantilever breakfast bars, reach up to 12 feet without supports, becoming social hubs that are impervious to wine spills and hot serving dishes. Monolithic design principles like this are rising in popularity where counter top materials flow seamlessly into built in benches and table tops for continuity in appearance. Illuminated: Backlit sintered stone slabs are becoming showpiece elements in open kitchens, serving as sources of ambient lighting during eveninngen hangs.

Bathroom Applications of Sintered Stone

Spa-Like Vanities with Waterproof Surfaces

The non porous structure of sintered stone doesn’t absorb water and makes it the perfect choice for bathroom vanities when daily water splash and humidity come into place. Not only is its surface highly impervious to mold and other bacterial growth—an important consideration given that in wet bathroom environments, 78% of vanity failures are due to moisture (Bathroom Design Trends Report 2023)—but it remains durable much longer than other materials such as natural stone or wood. Top manufacturers produce full-slab sintered stone vanities with integrated edges, enabling designers to carry the same pattern from the counter down to the cabinets for a unified, spa-like look. They can take a hit from water spots, while high-gloss versions reflect the play of light in a modern, minimalist bathroom.

Steam-Resistant Shower Wall Panels

Designed to withstand long-term steam exposure, sintered stone shower walls look as good as new even in hot, humid sauna-like conditions. Zero WARPING & Zero Discoloration: Recent industry tests demonstrate no warping or discoloration after 500+ hours of 100% humidity exposure - outperforming ceramic tiles, marble, and acrylic panels. Full-height sintered stone applications eliminate harmful grout lines, where spa mildew usually grows, and simplifies cleaning. Because the material is thermally stable, you can pair it with steam-shower systems, resulting in a monolithic wall that holds the heat. Designers are using neutral sintered stone walls with added integrated LED lighting to create luxury hotel-like bathroom experiences.

Sintered Stone Flooring Solutions

Large-Format Tile Installations

Sintered stone floors feature larger slabs so that grout lines are minimal and homogenous surfaces are perfect for an open floor plan. Sizes are frequently larger than 60 x120, decreasing the installation time by 30% compared to those of conventional tile. Resistant to lippage yet yielding to structural movement, these monolithic surfaces are the innovative alternative to rigid materials. In living areas, this design create unobstructed visual lines for a visual flow and less grooves to collect dirt.

Radiant Heating System Compatibility

This mineral-derived flooring better conducts heat from in-floor systems than energy impeding concrete. This is in contrast to natural stone which can dangerously and unpredictably remain at 65° F to 85° F, yet still run the risk of cracking under the spa's weight. Thermal ConductivityThese are the results of a thermal test that demonstrates 7% better efficiency compared to porcelain. The lack of porosity makes the pad less likely to absorb moisture which in turn will extend the life of those heating elements throughout the winter months.

Commercial-Grade Durability for Homes

Withstand stiletto heels, pet claws, and furniture drag without visible wear. Sintered stone achieves a 7-8 Mohs hardness rating—surpassing granite—coupled with 20,000+ PSI compressive strength. Impact resistance testing reveals 89% less chipping than ceramic tiles after five years. This endurance eliminates replacement cycles common with vinyl or laminate flooring.

Cost vs Value: Sintered Stone Investments

While sintered stone carries a 15–30% higher upfront cost than premium quartz or granite, its long-term value proposition reshapes traditional ROI calculations. Material prices typically range from $50–$200 per square foot, with installation adding $30–50 per square foot due to specialized handling requirements.

The investment pays dividends through decades of maintenance-free performance—unlike natural stone, it requires no sealing, resists thermal shock up to 1,400°C, and maintains color integrity under UV exposure. A 2024 construction materials study revealed sintered stone surfaces save $740–$1,200 in maintenance costs over 15 years compared to engineered alternatives.

For commercial projects, its commercial-grade durability reduces replacement cycles, while residential installations see 92% retention of resale value for kitchen upgrades featuring full-slab applications. The material’s lifecycle costs position it as a strategic choice for design-forward renovations prioritizing longevity over initial savings.

Selecting Sintered Stone Slabs for Your Project

Matching Veining Patterns Across Rooms

The natural-looking veining within sintered stone allows for seamless flow between kitchens, bathrooms and living space. For open concept applications or where there are no visible back splashes, install full slabs for continuous pattern appearance. The leading companies have digital pattern-matching capability allowing the veining to align seamlessly from one slab to the next – especially useful for waterfall islands or floor-to-ceiling feature walls. This method turns individual surfaces into harmonious design statements, giving them room for different uses.

Finish Options: Matte vs Polished

Matte finishes do well in high-use areas such as kitchen countertops, as they resist scratches and conceal fingerprints. Polished versions bounce light to make smaller spaces appear larger, such as bathroom vanities or accent walls. And recent additions are the textured finished, such as the faux stone which can be more pleasing to the touch. Factor in foot traffic and how often you want to clean them: polished ones need sealing every now and then in wet areas but matte surfaces keep looking new with very low maintenance.

FAQ Section

What is sintered stone made from?

Sintered stone is comprised of natural raw materials like quartz, feldspar, and clay that are compressed and baked at high temperatures.

Why is sintered stone preferred for kitchen countertops?

Sintered stone is preferred because it is durable, stain and heat-resistant, non-porous, and does not require sealing.

How does sintered stone contribute to modern renovations?

Sintered stone's aesthetic versatility, lightweight nature, and durability make it ideal for modern renovations, offering seamless integration with contemporary designs.

Are there any maintenance requirements for sintered stone surfaces?

Sintered stone surfaces require minimal maintenance. Unlike natural stone, they do not need sealing and are resistant to thermal shock, stains, and UV exposure.

What are the cost considerations for sintered stone?

While sintered stone may have a higher upfront cost than other surfaces, its long-term value includes maintenance savings, durability, and high resale value retention.

EN

EN AR

AR NL

NL FR

FR DE

DE IT

IT PT

PT RU

RU ES

ES