What Makes Sintered Stone Slabs Unique?

Composition and Manufacturing Process

Sintered stone slabs are made from natural stuff like clay, quartz, and feldspar. These materials get transformed when exposed to intense pressure and heat, kind of like what happens deep underground where real stone forms over time. The way these slabs are manufactured gives makers total control over things like how thick they want the slabs, their colors, and even the surface texture. Because of this level of control, we end up with something that works really well while looking great too. Another plus is that this production method actually cuts down on waste materials compared to traditional approaches, so it makes sense environmentally speaking. Even though they're big, these slabs stay strong enough to hold up in kitchens and bathrooms at home or in office buildings and restaurants where durability matters most.

Durability Beyond Natural Stone

What really sets sintered stone apart from the crowd is how tough it actually is compared to those old school natural stones we all know, granite and marble included. These stones are built to take a beating without chips or cracks forming, which makes them great choices when someone needs something solid for their home or business space. Tests have shown these thick slabs handle pretty much anything thrown at them, whether it's dropping heavy objects or constant foot traffic across floors. The bottom line is that sintered stone keeps looking good year after year while still performing better than most regular natural stones on the market today.

Heat & Scratch Resistance for Countertops

Sintered stone countertops can handle serious heat, standing up to temps around 300 degrees Celsius without breaking a sweat. That means cooks can set down those scorching hot pots straight from the stove without fearing any marks on their counter. The material's compact nature also gives it amazing scratch protection. Unlike regular granite which gets dented easily, sintered stone resists those annoying kitchen scratches day after day. For kitchens specifically, this stuff works wonders because it combines practical durability with that sleek modern look homeowners want these days. No need to sacrifice style for something that will actually last through years of cooking chaos.

Design Versatility of Sintered Stone

Mimicking Natural Materials Seamlessly

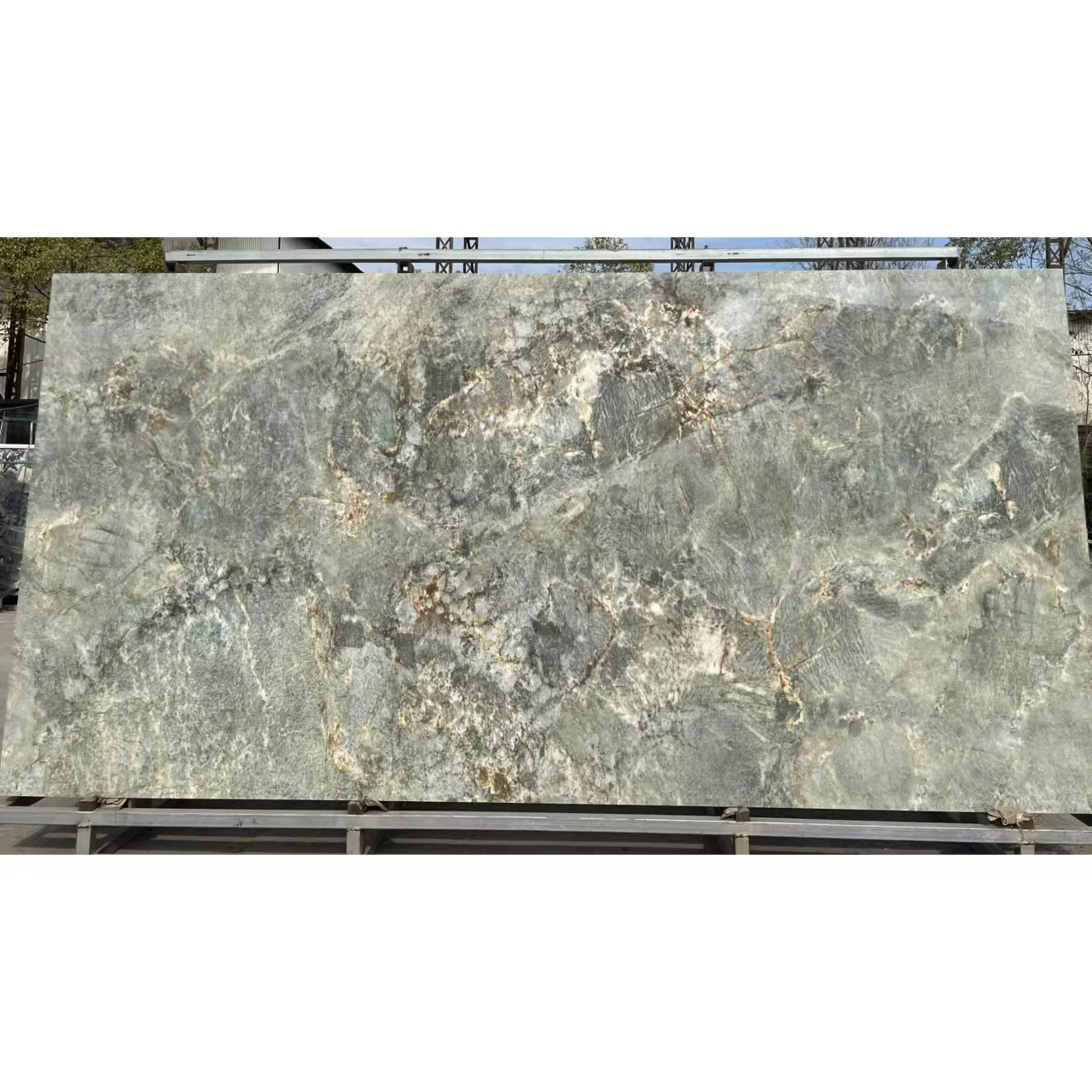

Sintered stone does a great job of looking just like real natural materials, offering that high-end look of marble, granite, and even concrete but usually costing much less than these options. The reason behind this? Advanced production methods let manufacturers craft detailed patterns and textures that would be impossible with traditional stones. Interior designers love working with sintered stone because it gives them so many creative possibilities when designing modern spaces that still feel elegant. What's really cool is how well it works across different architectural styles too. A kitchen backsplash made from sintered stone can match traditional cabinetry just as easily as it complements ultra-modern appliances, making it a smart choice for homeowners wanting something beautiful without breaking the bank.

Customization Options for Modern Kitchens

Customization matters a lot these days in kitchens, and sintered stone really steps up with all sorts of color options and different surface looks. The material adapts well to what people want in their space, whether they go for something traditional or really bold and modern. Plus, since we can cut it to fit almost any size or thickness needed, this stuff works great in all kinds of kitchen setups. Think about those big island counters or narrow bar areas where space is tight. Many manufacturers offer special finishes too, which give surfaces interesting textures while actually helping them last longer through daily wear and tear. That makes sintered stone pretty good for anyone wanting to create something truly unique in their kitchen without compromising on quality.

1600x3200mm Slab Applications

Sintered stone slabs that measure 1600x3200mm have become pretty much standard across the industry because they cut down on visible seams, giving buildings a much more seamless appearance overall. The consistency of this size works really well for big kitchen countertops and island installations where keeping the design looking continuous matters most during construction. When builders go with these bigger slabs, there's just less work involved in maintenance over time, plus the final look tends to feel more modern and put together. Spaces get transformed from something ordinary into something quite special when these materials come into play, combining practical features with contemporary style elements. No wonder we see them showing up everywhere now, whether in home kitchens or high end office spaces looking for that clean, sophisticated finish.

Sintered Stone in Kitchen Design

Worktops That Withstand Heavy Use

Sintered stone worktops hold up really well in busy home kitchens and even in commercial environments where wear and tear is constant. The material can take a lot of punishment while still looking great after years of use. These surfaces resist common problems like staining from spilled wine or coffee, scratching from knives, and cracking when exposed to sudden temperature changes. Home cooks appreciate how they keep their color and shine despite daily chopping, slicing, and hot pots being placed directly on them. Another big plus is that since sintered stone doesn't absorb liquids, food particles and bacteria have nowhere to hide, making cleaning much easier than with other materials. For anyone wanting a countertop that combines good looks with serious toughness, especially in households where cooking happens frequently, sintered stone offers excellent value over the long term.

Creating Cohesive Backsplash Systems

Sintered stone works great for kitchen backsplashes too when paired with countertops, creating a look where everything just flows together without any awkward breaks between surfaces. The material really stands out because it looks amazing while standing up to all sorts of messes in kitchens. Spills don't stick around long since the surface resists staining so well, plus cleaning takes no time at all making it perfect for those who cook regularly. There are tons of color choices available these days ranging from bold whites to deep blacks, allowing homeowners to pick something that actually matches what's already there instead of fighting against an existing color scheme.

Edge Profiles for Contemporary Aesthetics

Sintered stone comes with all sorts of edge options these days - think beveled edges, rounded corners, or just plain straight cuts. The flatter edges give off that clean modern vibe many people want nowadays, whereas those rounded ones tend to make things feel a bit warmer and less harsh looking. Kitchen designers love this because it really does affect how everything looks together. Some folks might prefer something sharp for their countertops, others go for softer lines depending on what kind of space they're creating. Homeowners who take time picking out the right edge profile end up with kitchens that look great and work well too, since certain shapes actually make cleaning easier around sink areas or stove tops.

Cost-Effective Luxury Solution

Price Comparison with Quartz and Granite

For anyone designing kitchens these days, sintered stone slabs stand out as something better than quartz or granite when we talk about getting good value for money. Industry reports keep showing similar results time after time: sintered stone tends to be priced around 20 to 30 percent lower than comparable natural options like quartz and granite. What's interesting is that this price difference doesn't mean sacrificing quality either. Many homeowners and interior designers find themselves drawn to sintered stone because it offers that luxurious look without breaking the bank. Take our neighbor Sarah who remodeled her kitchen last year she got exactly what she wanted in terms of appearance but paid significantly less than what granite would have cost her.

Long-Term Value of 3C-Certified Slabs

People who go for 3C certified sintered stone slabs tend to see real value over the years because these materials just hold up better than most alternatives. According to some research out there, going with good quality sintered stone actually cuts down on maintenance expenses somewhere around 40 percent. That makes sense when thinking about how often we replace or fix other types of countertops. The 3C certification isn't just marketing fluff either. It basically tells us that the stone has passed tests for quality, looks great, and doesn't require much upkeep. For kitchens where spills happen daily and heat from cooktops is common, this kind of slab stays looking new longer while saving money on fixes down the road.

Sustainable Manufacturing Innovations

Eco-Friendly Production Methods

Sustainability lies behind how sintered stone gets made. Manufacturers focus on cutting down waste and using resources wisely throughout production. They've managed to build up quite a reputation for making stones that don't harm the environment too much. The industry has changed quite a bit lately thanks to new tech stuff coming in. Factories now emit way less carbon than they used to because of better equipment and processes. For homeowners looking at kitchen renovations, choosing sintered stone isn't just smart from a durability standpoint either. More people care about where their materials come from nowadays. When someone walks into a store and sees those sleek surfaces knowing they helped protect the planet while doing so, well that matters to folks who want to live greener lives without sacrificing quality or style.

Recyclability of Sintered Materials

Sintered stone looks great and is actually good for the environment too because it can be fully recycled. When these materials reach the end of their useful life, they don't just get thrown away. Instead, they can be properly disposed of in ways that allow us to recover valuable resources from them. Many companies now take old sintered stone countertops and turn them into brand new products, which cuts down on what goes into landfills and saves our precious natural resources. People who care about living sustainably find these countertops appealing since they fit right in with today's green building practices. For anyone designing a kitchen with sustainability in mind, sintered stone offers another solid option among the growing list of environmentally friendly choices available today.

EN

EN AR

AR NL

NL FR

FR DE

DE IT

IT PT

PT RU

RU ES

ES